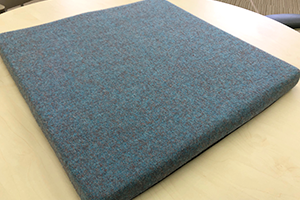

As part of our SDGs initiatives, in 2023 we launched the "Mirai Creation Project" to conduct plant tours, and to conduct manufacturing classes using end materials (scraps) from our plants at neighboring elementary and senior high schools.

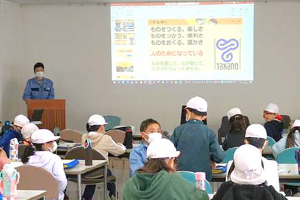

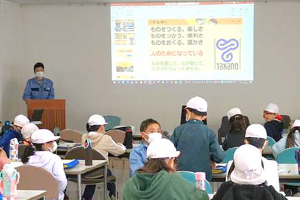

The following footage shows the company briefing, the manufacturing process of the chair, and the introduction of SDGs initiatives

In this issue, we report on the day of the event at Komagane City Akaho Minami Elementary School in Nagano Prefecture.

■Date : Tuesday, October 31, 2023

■Place: Takano Ina Factory

■64 children in the fifth grade of the elementary school took part in the event.

We had 64 children, the largest number of visitors per each factory tour since the start of the project.

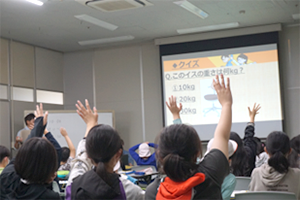

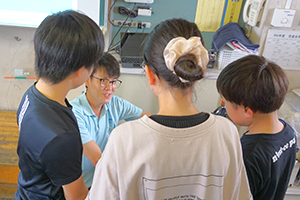

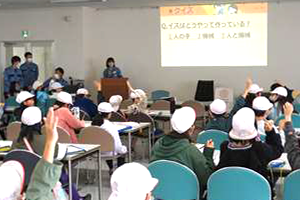

At the company briefing, we were pleased with innocent reaction of children, such as surprise at our company sales amount, active attitudes in participating in quizzes about chairs, etc.

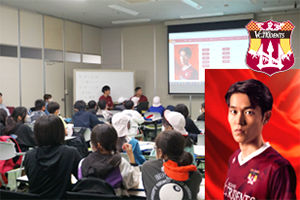

This time, the head of Healthcare Division also participated in the project for the first time, and talked to children about making welfare equipment and wheelchair cushions.

-

The school emblem of Ako Minami Elementary School, which I was made with 3D printers on the day, will be given away.

When we did the demonstration of our 3D printer, which children have never seen before, they were very interestingly observing it.

Factory tours

This time, factory tours were carried out by dividing them into three groups [A, B, and C] due to the large number of people.

The C group toured [Plating → Painting → Folding chair assembly line → Work pod → Pipe processing].

Children seriously listening to and taking notes of our explanation.

Plating

Painting

Processing

Move your heart and change your future through making things.

Move your heart and change your future through making things.

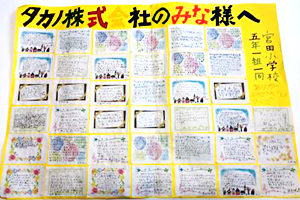

After the factory tours, many questions were raised by children.

They asked a wide range of questions, from simple questions to about workers.

We would like to introduce some of them to you.

"Q: Why do you have plants in your office?"

"A: It's an office, but it's like a living room.We can work comfortably when we have greenery."

"Q: Don't you run out of the plating solution?"

"A: We are always replenishing it, so we can keep it. Also, we are returning it to the Tenryu River after the purification."

"Q: How do you feel when you work?"

"A:We are working to let everyone enjoy sitting in or make them smile with our chairs."

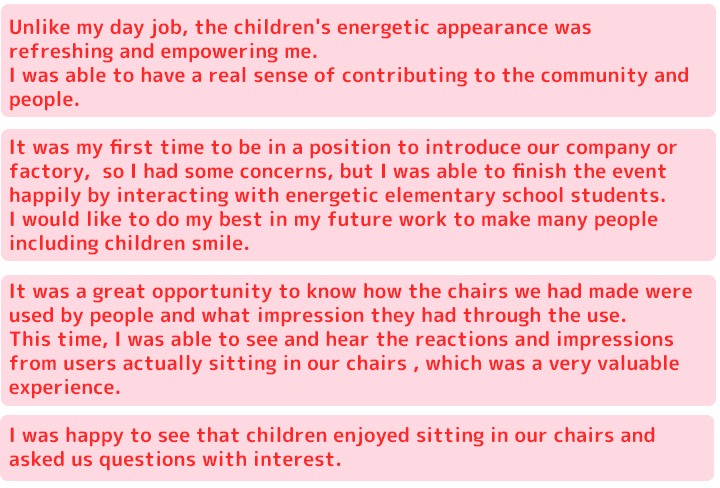

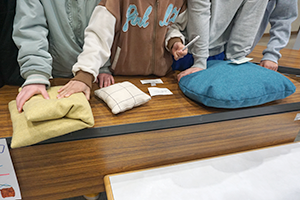

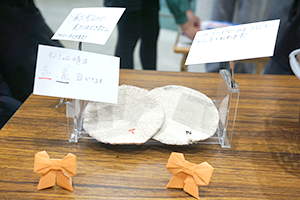

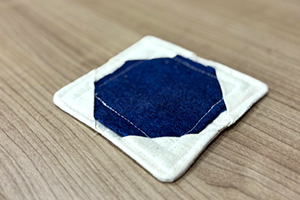

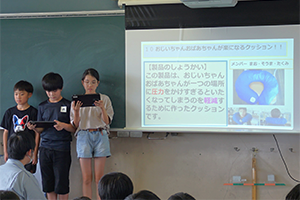

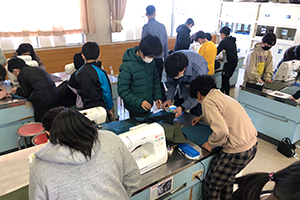

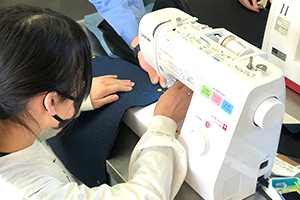

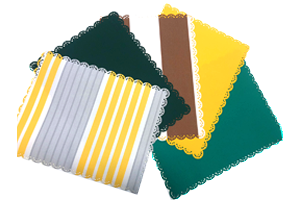

Finally, we had a class designed to encourage children to take away fabric and urethane scrap materials (end materials) and think about manufacturing.

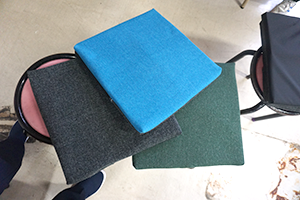

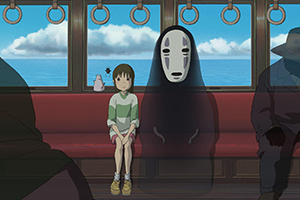

Comments from the persons in charge

We asked the persons in charge, who participated in this project for the first time , what they thought of today.

One of persons in charge was a graduate of Akaho Minami Elementary School.

Through the children's learning, we employees felt motivated to do our best in their future jobs.

We greatly thank all the teachers and children of Akaho Minami Elementary School for joining us!